-40%

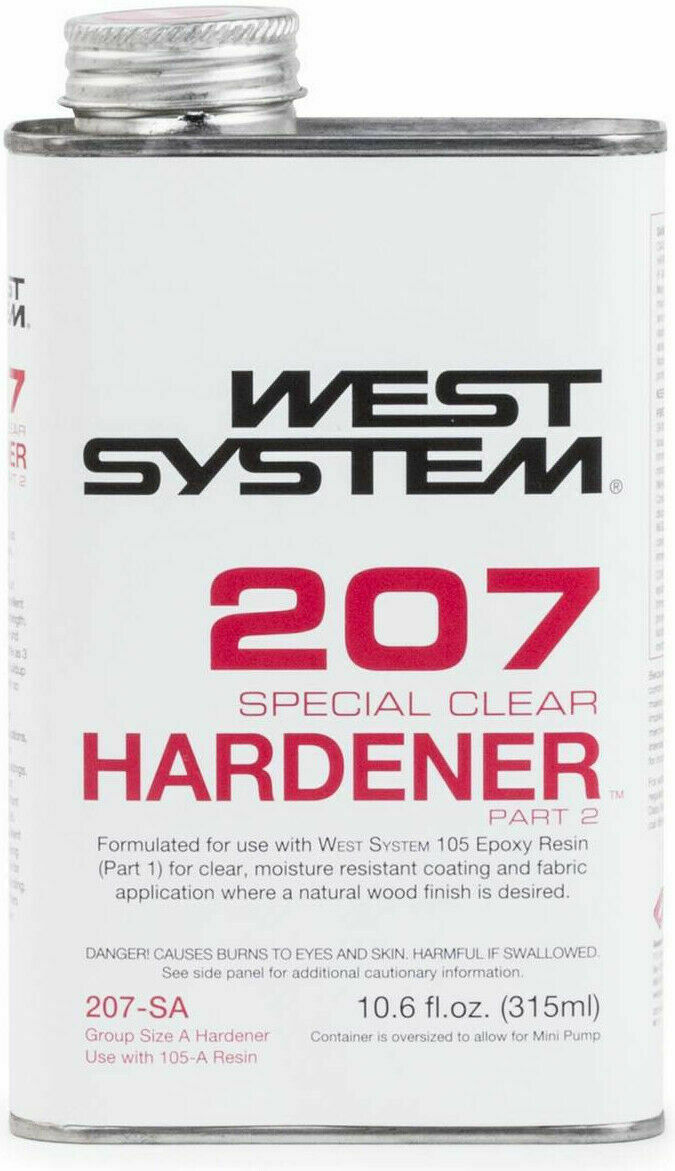

West System 207 Special Clear Epoxy Hardener (.66 pt)

$ 38.01

- Description

- Size Guide

Description

West System 207SA Special Clear Epoxy Hardener (10.6 fl oz)Brand New in Original Packaging

SKU: 207SA-WESTSYSTE

Features

Developed for coating and fiberglass cloth application

Provides clear, moisture-resistant, natural wood finish

Mix with 105 Resin in a 3:1 resin to hardener ratio

Blended with 105, will not blush or turn cloudy in humidity

Thin film applications roll out and tip off smoothly

Three coats or more can be easily applied in one day

Fewer coats are required to fill fiberglass weave

Makes building boats faster

Achieves excellent fiberglass wet-out characteristics

Won’t drain from vertical surfaces

Product Description

Blush-free 207 Special Clear Hardener from West System was developed for coating and fiberglass cloth application where an exceptionally clear, moisture-resistant, natural wood finish is desired. Blended with 105 Epoxy Resin (sold separately), 207 Special Clear Epoxy Hardener will not blush or turn cloudy in humid conditions. Thin film applications roll out and tip off smoothly, requiring less sanding in preparation for finish coatings.

Suitable for Professionals

Professional and first-time builders like 207 Special Clear Hardener because it is reliable, easy to use, as does not blush. Three coats or more can be applied in one day without additional surface preparation. Fewer coats are required to fill fiberglass weave and in most cases, the final coating can be sanded the following day. Boats can be built faster. Builders also appreciate the excellent fiberglass wet-out characteristics achieved with 105 Resin/207 Special Clear Hardener Mixture, yet it won’t drain from vertical surfaces like the very slow curing, low-viscosity epoxies.

Strong Physical Properties

The 105/207 Epoxy Mixture has strong physical properties, so it can be used as a structural adhesive for gluing and laminating. It has excellent compatibility with paints and varnishes. An ultraviolet inhibitor in 207 Special Clear Hardener helps provide a beautiful, long-lasting finish when used with quality UV filtering varnish. The 105/207 Epoxy Mixture cures clear and colorless.

Pouring Epoxy

Warming the resin and hardener to about 80-degree-F before dispensing will the epoxy’s viscosity, enhancing 207 Special Clear Hardener’s good flow characteristics. Epoxy resin and hardener cans may be safely warmed in a water bath. To reduce bubbling, seal the surface before pouring the deeper coating.

Clear Casting Table Tops

Pouring a thick coating or casting onto a table top, bar or counter top creates a popular effect. The 207 Special Clear Epoxy Hardener is especially well suited to these applications. A 1/4-inch thick coating of 105 Resin and 207 Hardener is deep enough to cast objects such as memorabilia into the epoxy for decorative accents.

Brush One or Two Thin Coats

To prevent bubbles outgassing from the surface, brush one or two thin coats of epoxy onto the surfaces. Allow this to reach gelation (about 6 hours at room temperature) before pouring epoxy. If you wait more than 18 hours before pouring your deeper layer of epoxy, be sure to sand the seal coating before pouring the epoxy mixture.

Removing Air Bubbles

A handheld propane torch or heat gun can be used to break the epoxy’s surface tension and help remove air bubbles. First, give the poured epoxy a couple of minutes to self-level. The bubbles should rise to the surface. Then move the heat source rapidly over the area (at roughly one foot per second) to avoid overheating the epoxy. You don’t want the heat source to make the epoxy gel or smoke.

A Beautiful Finish

Allow the final epoxy pour to cure for 24 hours before sanding the surface. When fully cured, the epoxy will sand to a dust. 105 Epoxy Resin with 207 Special Clear Hardener is compatible with many varnishes and polyurethanes. If your clear coated surface will be exposed to sunlight, add a topcoat of the UV protective varnish or a high-quality 2-part polyurethane.

What's in the Box

West System 207SA Special Clear Epoxy Hardener (10.6 fl oz)

Specifications

West System 207SA Special Clear Epoxy Hardener

Product name: West System 207 Special Clear Hardener

Product code: 207-SA

Chemical family: Polyamine mixture

Quantity: 10.6 fl oz

Compatibility: 105-A Resin

Intended product uses:

Curing agent for epoxy resin

Applying fabric, clear finish, general bonding, and barrier coating

Pot life at 72-degree-F (22-degree-C): 20-26 minutes (100g cupful)

Cure to solid (thin film): 10-15 hours

Cure to maximum strength: 4-7 days

Working time (thin film): 100-120 minutes

Minimum recommended temperature: 60-degree-F (16-degree-C)

Coating coverage:

Saturation coat porous surfaces: 90-105 sq ft (8.5-10 sq m)

Buildup coats non-porous surfaces: 120-135 sq ft (11-12.5 sq m)

Shipping

Payment

Returns

Feedback

Shipping for this item is free in the Continental US Lower 48 states only. Shipping Fees include all handling & insurance.

For Domestic Shipping to the Lower 48 States:

All shipping prices include shipping, handling and insurance (if necessary).

For Domestic Shipping to Alaska, Hawaii, Puerto Rico, US Territories, APO & FPO:

For many items to these destinations there will be an additional shipping fee. The shipping costs may be calculated on the Shipping and Payments tab by entering your Zip Code. Free shipping is for the lower 48 only

For International Shipments:

All international orders are managed through eBay's Global Shipping Program. Please see the Shipping Tab for full costs.

Hotels:

Unfortunately at this time we do not ship to hotels.